“Water, water everywhere,” goes the old rhyme. And while 71 percent of the Earth is water, this important resource is threatened by harmful practices that can contaminate or drastically drain the world’s water supply. In order to combat these threats, a variety of groups — both on Boston University’s campus and elsewhere — have been making moves in innovation and education regarding one of Earth’s greatest resources.

“Water is an issue that is gaining momentum around the world in many different industries and in many different applications,” said Adam Weiner, researcher and mechanical engineering graduate student at the Massachusetts Institute of Technology. “That’s why it’s exciting.”

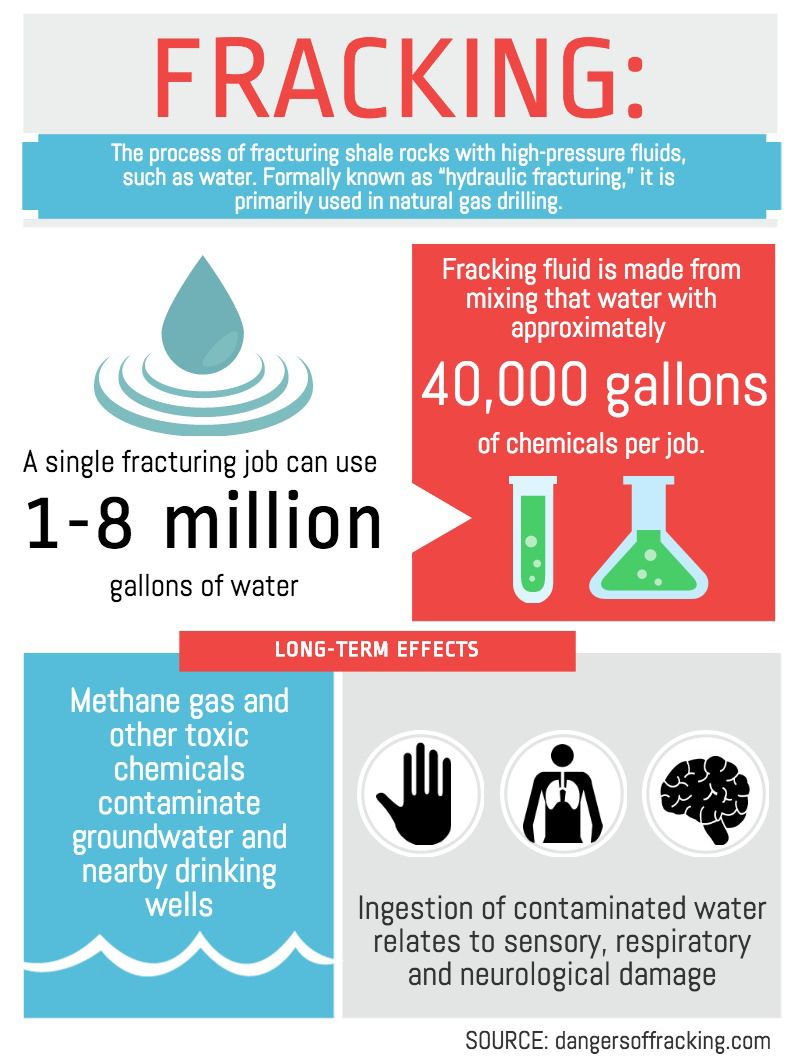

With a range of 1 to 8 million gallons of water and approximately 40,000 gallons of chemicals used per job, according to dangersoffracking.com, natural gas fracking follows the “what goes in, must come out” principle by nature. Unfortunately, what “comes out” is contaminated groundwater, a consequence that has brought about controversy and water purification concerns in recent years.

In response to this undesirable byproduct, a team of researchers from the Center for Clean Water and Clean Energy at MIT and King Fahd University of Petroleum and Minerals in Saudi Arabia studied a method for improving the treatment of water following the fracking process. The team’s formal paper was published last week in the December 2014 issue of Applied Energy.

Hydraulic fracking is a process used in drilling natural gas wells. When a well is drilled, millions of gallons of sand, water and chemicals are injected into the well in order to crack the shale, a certain type of rock, surrounding the gas, allowing it to flow more freely. While fracking provides easier access to clean-burning natural gas, critics have cited the process’ large-scale removal of freshwater, chemical contaminations and work-cite accidents as reasons to stop fracking.

“The idea of our study was to take an existing desalination technique called electrodialysis, which uses electric fuels to move ions out of water, and to take this existing technology and apply it to a totally different application than what it has been traditionally used for,” Weiner said.

Electrodialysis is well suited for cleaning the type of low-saline, leftover water that fracking leaves behind, Weiner explained, making it a simpler and more economic solution than thermal desalination, which uses heat energy to separate water from its impurities.

“The problem with this [thermal] desalination technique is that it’s quite energy intensive, so the cost can be quite high for treating,” he said. “But we found that overall, our treatment costs are quite a bit lower.”

Still, Weiner admitted that the method is by no means perfect and will require plenty of prototyping before coming close to putting the electrodialysis technique into practice.

“Any time you introduce a membrane [desalination technology], there are concerns with the performance of the membrane over time,” Weiner said. “That’s because membranes are quite sensitive to oil, which can significantly damage the membrane.”

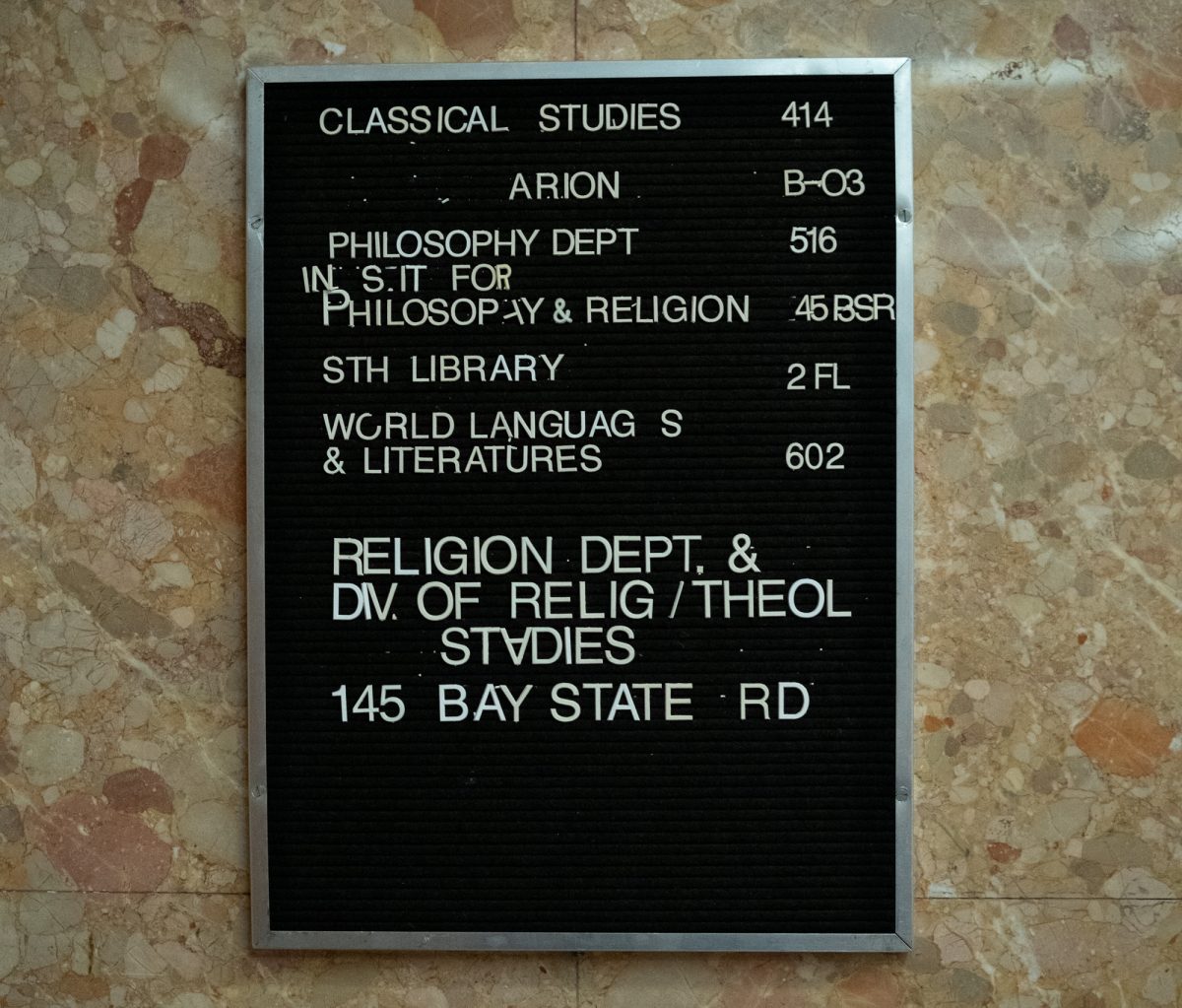

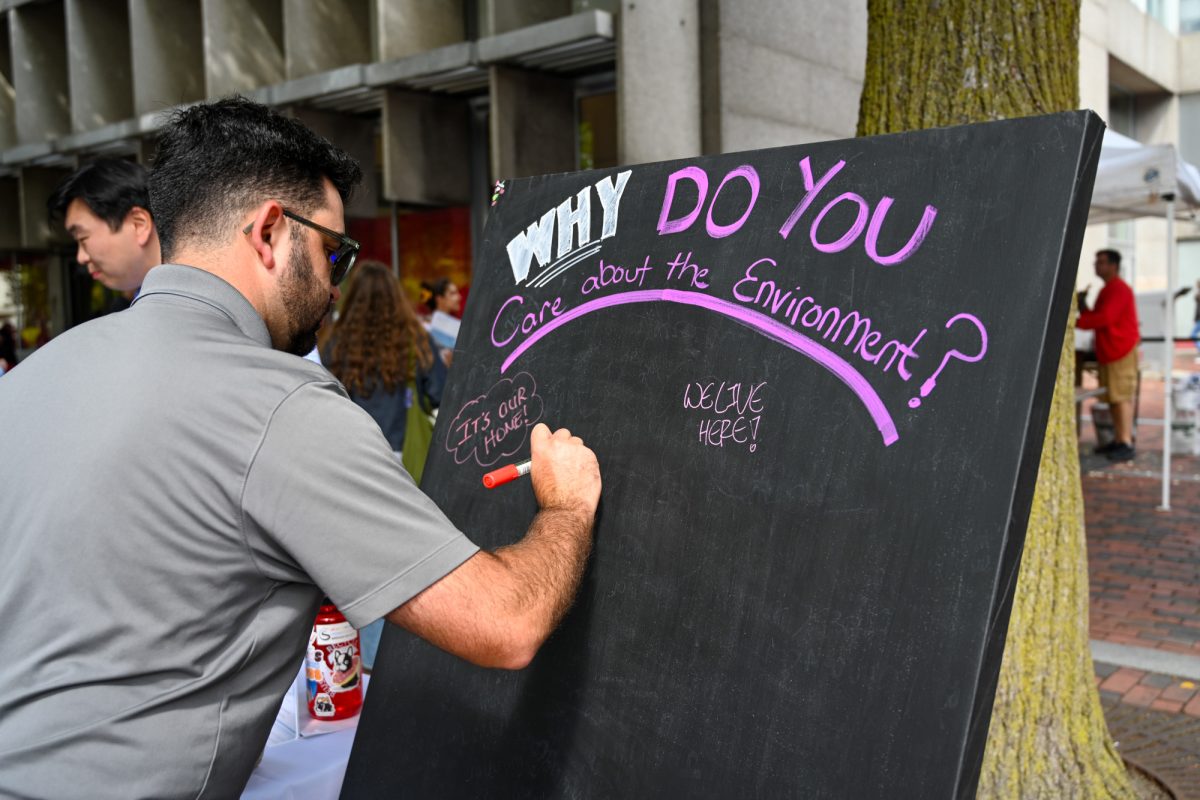

But innovation and education hold equal value in the quest for clean, drinkable water across the globe. Boston University’s Environmental Student Organization involves itself with the latter piece of the environmental puzzle in many ways.

“Our activities cover volunteering in the Greater Boston area, advocating for environmentally-friendly policies on campus and in Boston and education for the BU community as a whole,” said Andrew Held, a junior in the College of Arts and Sciences and president of the ESO. “For example, to raise awareness about water issues in third world countries, we had a dunk tank in the GSU [George Sherman Union] Plaza last year.”

BU Dining Services has also focused its efforts on water and finding the most sustainable way to use it. Sabrina Pashtan, the sustainability coordinator of BU Dining Services, said decreasing BU’s water consumption is an area of focus that receives continual attention.

“Since about 2007, we have been ‘tray-less’ in the dining halls. This saves thousands of gallons of water each year from not having to wash them,” Pashtan said. “We also use low-flow aerators on some of our faucets for both prep sinks and hand sinks, which reduce water flow to 0.5 to 1.5 gallons per minute.”

In terms of innovation, BU’s installment of sustainable technology also marks an effort to limit overconsumption of water.

“Our new dish machines in the GSU, West Campus [dining hall] and Marciano Commons are the most energy and water efficient models on the market and collectively save millions of gallons of water per year through their advanced technology,” Pashtan said.

Although more focused on cleanliness, the MIT and KFUPM partnered team also sought out a method for managing water as a resource. Weiner said global accessibility to clean water is an ultimate goal of specialized research.

“Specifically with this project, I’m excited by the opportunity to solve a major problem currently facing hydraulic fracking,” Weiner said. “And to be able to manage that water in an environmentally responsible way.”

Russ Cohen • Nov 3, 2014 at 11:02 am

I am sorry this article did not mention Because Water (http://becausewater.org/), started by Matt Thomas (https://www.linkedin.com/pub/matt-thomas/48/9b2/389). Because Water has been active on the BU campus.