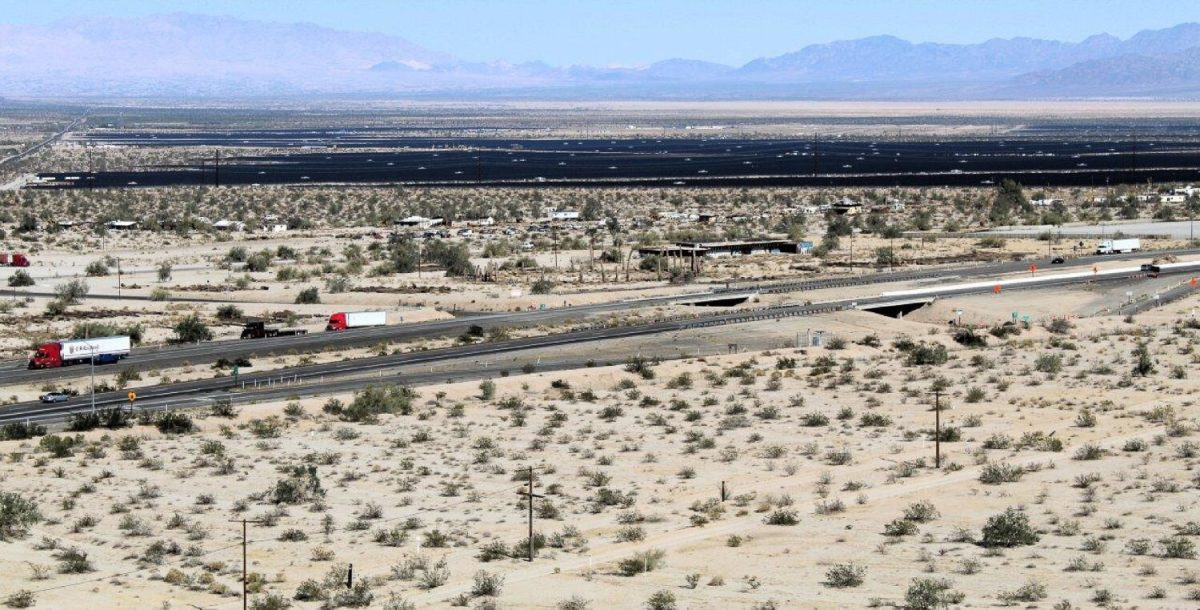

Imagine having to balance the stresses of a regular college student while also building a 325 pound, all-terrain vehicle, loading it onto a box truck and driving it halfway across the country for a national racing competition.

Boston University’s Baja SAE team, comprised of students and faculty who share a passion for cars and engineering, is dedicated to this goal.

The Society of Automotive Engineers sponsors three annual design competitions where more than 100 colleges and universities from around the world can enter self-designed and self-built vehicles.

Sappan Gupta, the president of BU Baja and a junior in the College of Engineering, said the team is preparing for their upcoming competition in Peoria, Illinois on June 3. The team’s primary objective is to create and manufacture an off-road to enter in the June competition.

“You’d be surprised with how many people come up with different ideas and different views of how to fit their car into the rules,” Gupta said.

These rules include building a single-seat, all-terrain sporting vehicle that is also a “prototype for a reliable, maintainable, ergonomic, and economic production vehicle that serves a recreational user market,” according to the SAE website.

The team has been focused on designing the rolling chassis for their car — which includes the vehicle’s frame, suspension and wheels — which Gupta said is an integral component to the overall design of the car.

“Our current car has been in the making for about three years,” Gupta said. “Over that time, we’ve been designing the frame to get a rolling chassis.”

The BU team hasn’t entered a competition since 2017, instead waiting to perfect their design for the upcoming 2020 competition.

The team is currently undergoing what Gupta said is their biggest challenge yet. For the upcoming competition, they’ve decided to make the car’s gearbox from scratch, compared to previous competitions where they’ve used one that is pre-made.

Manufacturing one from scratch, Gupta said, can improve the speed and reduce the weight of the vehicle.

“We’re trying to design [the gearbox] from scratch, which is a big endeavor for a small team like us,” Gupta said. “We’re hoping that this is what’s going to throw us into the higher tier of the teams at the competition.”

Vehicles are judged on which team can utilize engineering skills in order to meet various design goals, which mainly include the functionality of the car as a whole and its individual segments, according to the 2020 version of the Collegiate Design Series Baja SAE Rulebook.

Over the course of the team’s time at BU, they have struggled with decreasing membership, said Domenico DiMare, the club’s graduate advisor and member of the club for four years prior to graduating.

DiMare said the team has existed at BU for around 15 years, but as seniors graduate, the team has to regroup.

“What’s happened, sadly a couple of times, is that it’s had to restart as seniors leave and then there is no team,” DiMare said. “Then about a year later, some people hear about it and start it up again.”

The inconsistencies in membership have hindered the team’s performance in the past in comparison with other teams that are able to improve upon their vehicles over the course of many years, DiMare said.

“Lots of other teams have been doing the same thing for 20 years and have built that knowledge base,” DiMare said. “For us, sadly, every five to eight years that knowledge base disappears and we’ve had to start from scratch.”

The team’s smaller size, which includes around 20 members, has made it difficult for the club to consistently progressing in recent years.

But despite the challenges, the team has made accomplishments including designing a custom suspension in 2018, which DiMare said was one of their greatest achievements.

“This allowed the cars to traverse much bumpier terrain, like bigger boulders and rocks at faster speeds,” DiMare said.

While the majority of the members of the club are engineering majors, the competitions are also judged based on a business component. Andrew Chen, the treasurer of the club and a junior in the College of Engineering, said vehicles not only have to be designed well, but also have to be cost-effective.

“The whole point is that you’re supposed to design the car and then sell it to industry leaders,” Chen said. “Generally, we are allocated a budget by the BU mechanical engineering department.”

Baja is a competitive and intense commitment, but it is also a lot of fun, vice president and sophomore in the College of Engineering, Sean Richichi, said.

“This past weekend we did a test run at our advisor’s house,” Richichi said. “It was a lot of fun getting the group together, getting muddy. It’s hard to describe it until you’ve done it, but it’s just unreal.”